NEWSLETTER

Z-AXIS and Bear – a powerful combination

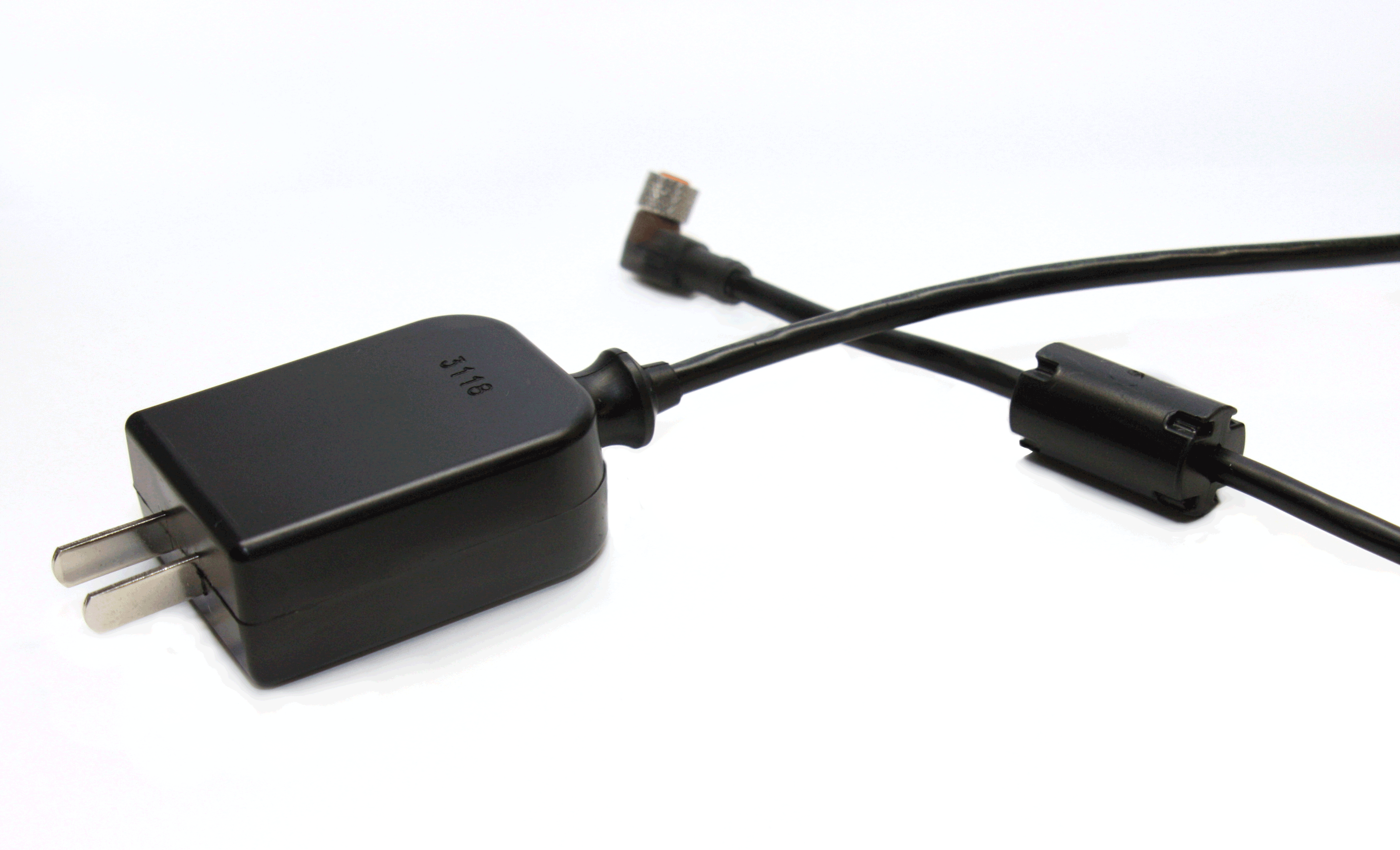

Z-AXIS has been doing specialty power supplies since we started the company in 1989, for our own rugged CRT monitors. Realizing we had a unique competence in power supply design, we began marketing it under our Bear Power Supplies brand in 2003.

Today we are one of a very few companies who will do a full-custom power supply design for customers. That has attracted a number of billion-dollar global medical equipment manufacturers to work with us.

We like to say “we do weird.” We meet their hard-to-achieve specs like very low leakage current, odd voltages, unusual form factors. And we do it for relatively small quantities, which suits their needs for specialized equipment that they may sell only a few thousand units of, as well as larger quantities up to the millions.

But what does that mean to our non-power supply customers?

Robust Systems

First, it means we have a lot of systems in place that you‘d normally only expect from a much larger contract manufacturer. Things that our medical equipment customers demand, such as:

- Robust corrective action systems

- A preventative maintenance schedule for every piece of equipment on the line

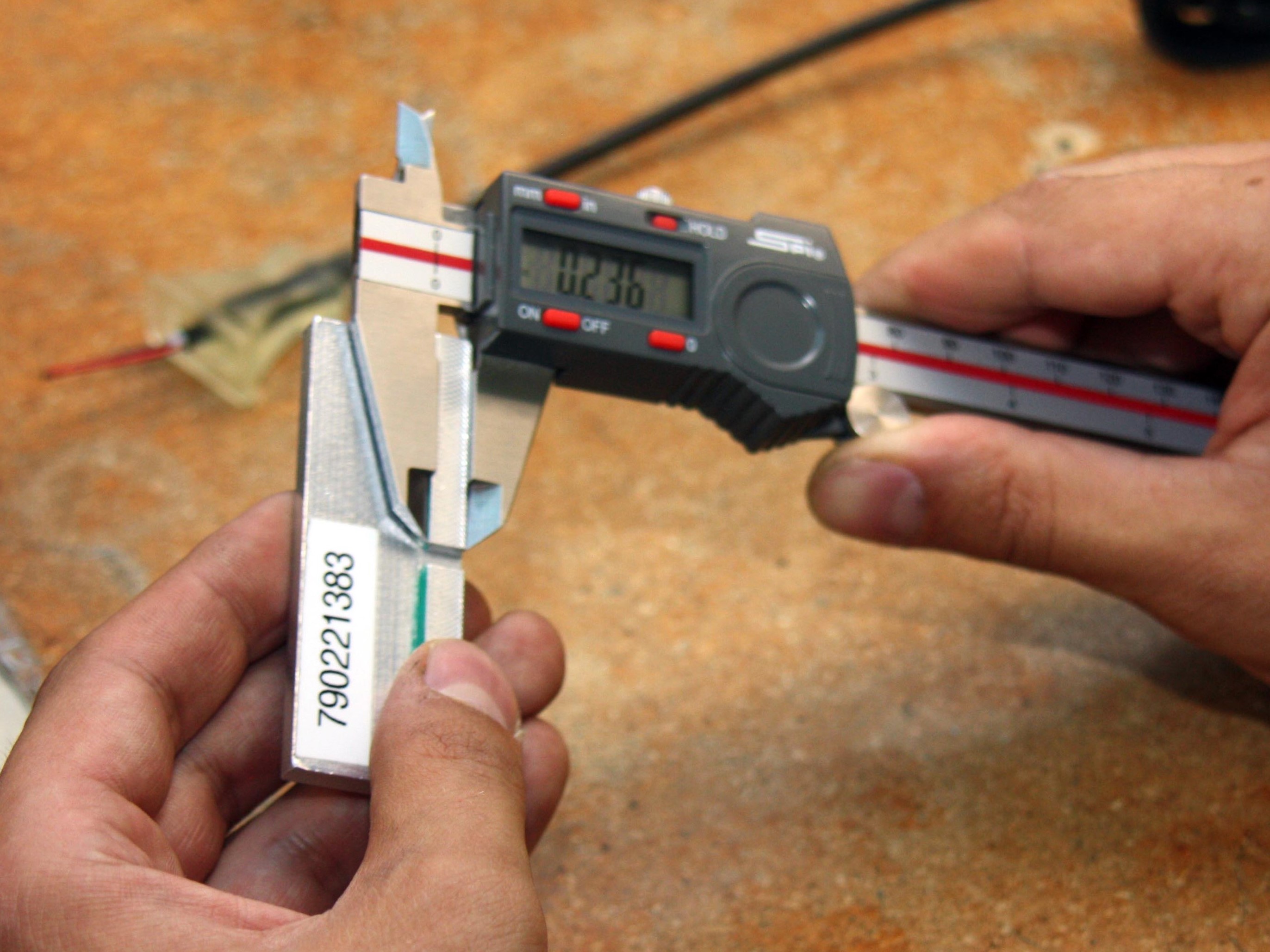

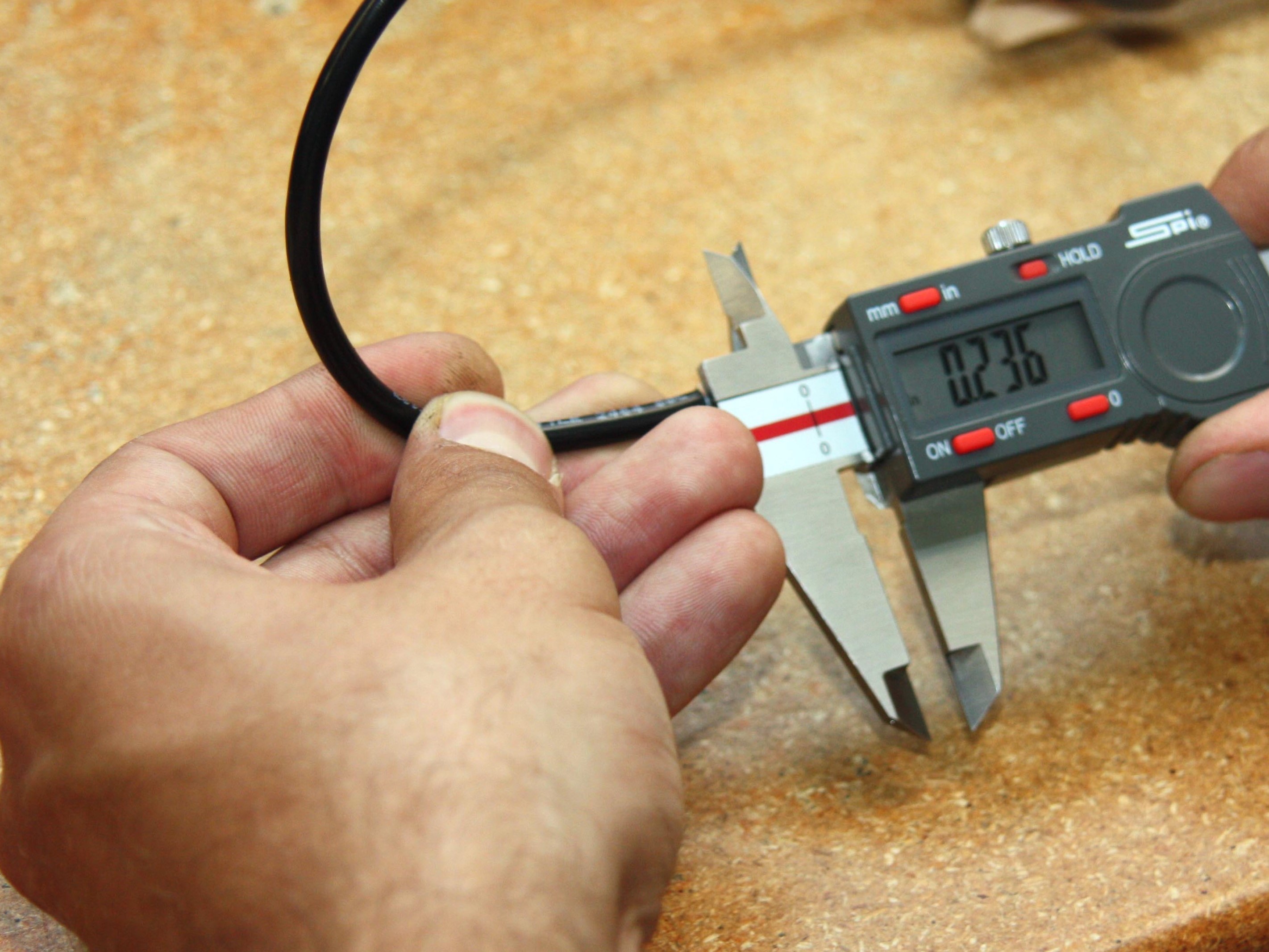

- Equipment that’s process-capable and validated on a regular basis.

- A quality team with five internal ISO auditors, and a manufacturing engineering staff of six – not just one or two people in these departments which is typical of most companies our size.

The Z-AXIS manufacturing engineering team validates fixtures on a regular schedule.

Having built these advantages, we don’t use them just for medical power supplies. We apply them to every job we do. This means that our employees have the tools they need to do exceptional work that they can be proud of. And it means that all of our customers enjoy the benefits that a billion-dollar medical company commands.

Yet we still give our customers all the advantages of working with a smaller supplier:

- You don’t have to be the biggest customer and buy $10M a year to be important.

- We are adept at quick changeover, routinely slotting multiple low- and mid-volume jobs between the high-volume runs as a common practice, not an after-thought.

Efficient Hand Assembly

You also get better cost and quality from Z-AXIS when you need a manual process to complete your board assembly. If your boards are nothing but SMT and can be produced by a fully-automated assembly line, this won’t matter to you. But if you need to drive a motor, solenoid, or other motions system, or a heat sink, or custom shielding – it matters.

Power supplies have a lot of large, chunky parts and their assembly really cannot be fully automated. So we have developed efficient processes for manual assembly over the years. We can move boards through it quickly, with high quality, and an efficiency that drives out cost.

Rare Design Skills

Most design firms can do embedded microprocessor work, and in fact that’s about half of what our design team does. Beyond that, every design firm has its core competencies. Some specialize in RF, others in vision systems. Our core design competencies are power and analog.

We’re very comfortable designing the power supply right onto your board. We have expertise with component selection, cost vs. lifetime vs. performance tradeoffs, and optimizing the layout of the power section. Most design firms will shy away from this, especially if high voltages are involved.

Analog goes hand-in-hand with power. And like power design, analog design skills are much less common than digital design skills. You need analog design any time you’re measuring or sensing something: whether it’s light, temperature, strain, pressure, a voltage or current. We understand how to create a circuit and interface it to the digital system using any of the interface bus standards you need.

More Power to You – and Us

Our expertise with power supply design and manufacturing, and our work with the world’s leading medical equipment manufacturers, benefits all of our customers and helps make Z-AXIS a great place to work.

Manual assembly steps are planned for efficiency and get the same attention to controlled process