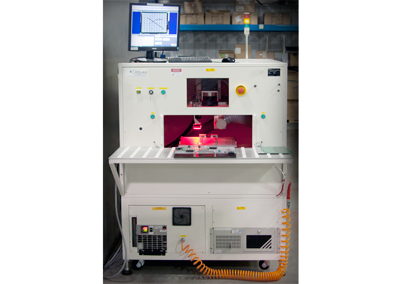

September 15, 2015 – Z-AXIS has added a new UV laser for depaneling printed circuit board assemblies at its contract design and electronics manufacturing center near Rochester, NY. The 20-Watt HT200 Series UV laser from Hylax Technology enables higher precision with no mechanical stress when separating individual printed circuit boards from arrays after assembly.

This offers significant advantages, in particular to Z-AXIS customers who are using the PCB assemblies in small, compact products. The UV laser makes extremely narrow and precise cuts in any shape, allowing Z-AXIS to hold much tighter tolerances on the finished board size than can be achieved with traditional pre-routed panels. Laser cutting also allows for components to be placed much closer to the edge of a board, maximizing the use of board area in small spaces.

The new UV laser expands Z-AXIS’ capabilities and complements its traditional depaneling tools and methods. The company’s in-house electronics design services department assists customers in creating array drawings for depaneling, whether the board layout is provided by Z-AXIS or the customer. The design engineers provide guidance on board design and depaneling methods to achieve the required tolerances and high reliability while balancing material costs, manufacturing costs and throughput.