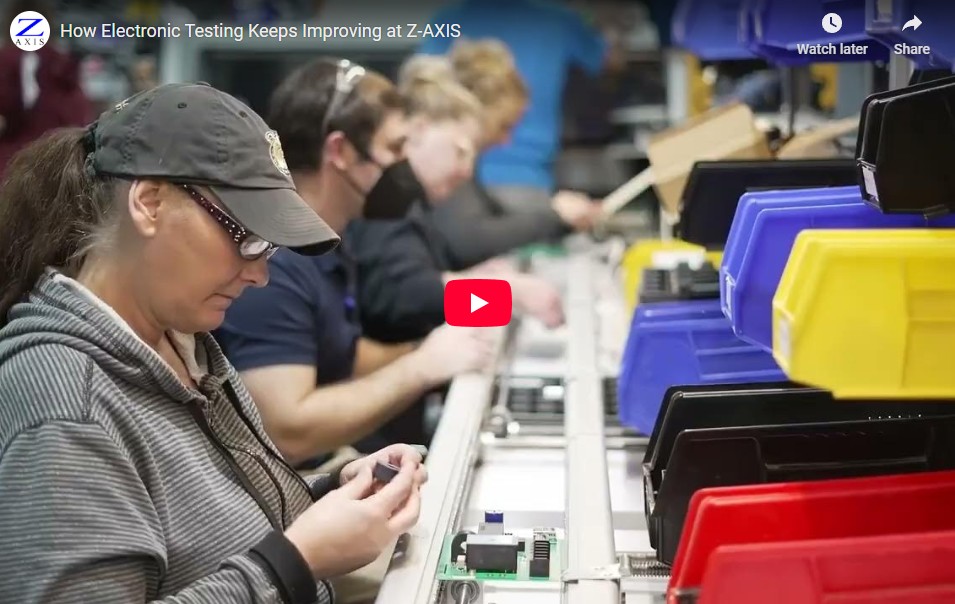

Z-AXIS performs electronic testing for almost every board that we make.Years ago, Z-AXIS didn’t test most of what we made. That’s not the case anymore. When you’re building boards that are used with life-saving medical devices, even a 98% success rate isn’t good...

Z-AXIS performs electronic testing for almost every board that we make.Years ago, Z-AXIS didn’t test most of what we made. That’s not the case anymore. When you’re building boards that are used with life-saving medical devices, even a 98% success rate isn’t good...

Production tools from Z-AXIS let us add value, remove costs, and deepen our understanding of customer projects..Boards that weren’t designed for manufacturability need a way to be held during production. That’s why Z-AXIS designs and builds fixtures, jigs, and other...

Production tools from Z-AXIS let us add value, remove costs, and deepen our understanding of customer projects..Boards that weren’t designed for manufacturability need a way to be held during production. That’s why Z-AXIS designs and builds fixtures, jigs, and other...

Additional services from Z-AXIS add value to the boards we build for you.Z-AXIS is known for electronic design and manufacturing, but we also offer a menu of additional services. We take an a la carte approach so that customers can order only what they need or combine...

Additional services from Z-AXIS add value to the boards we build for you.Z-AXIS is known for electronic design and manufacturing, but we also offer a menu of additional services. We take an a la carte approach so that customers can order only what they need or combine...

Z-AXIS has improved the way that we store and retrieve SMT parts. Recently, we installed four automated storage towers from Mycronic, the same company that makes our pick-and-place machines. The towers are 4 to 6 feet in diameter and almost 9 feet tall. The smaller...

Z-AXIS has improved the way that we store and retrieve SMT parts. Recently, we installed four automated storage towers from Mycronic, the same company that makes our pick-and-place machines. The towers are 4 to 6 feet in diameter and almost 9 feet tall. The smaller...

Electronics Prototyping at Z-AXISElectronics prototyping creates physical models that designers use to test and validate their ideas. It involves PCB assembly for the electronics and machining for the housing.Years ago, Z-AXIS created prototype boards by placing parts...

Electronics Prototyping at Z-AXISElectronics prototyping creates physical models that designers use to test and validate their ideas. It involves PCB assembly for the electronics and machining for the housing.Years ago, Z-AXIS created prototype boards by placing parts...

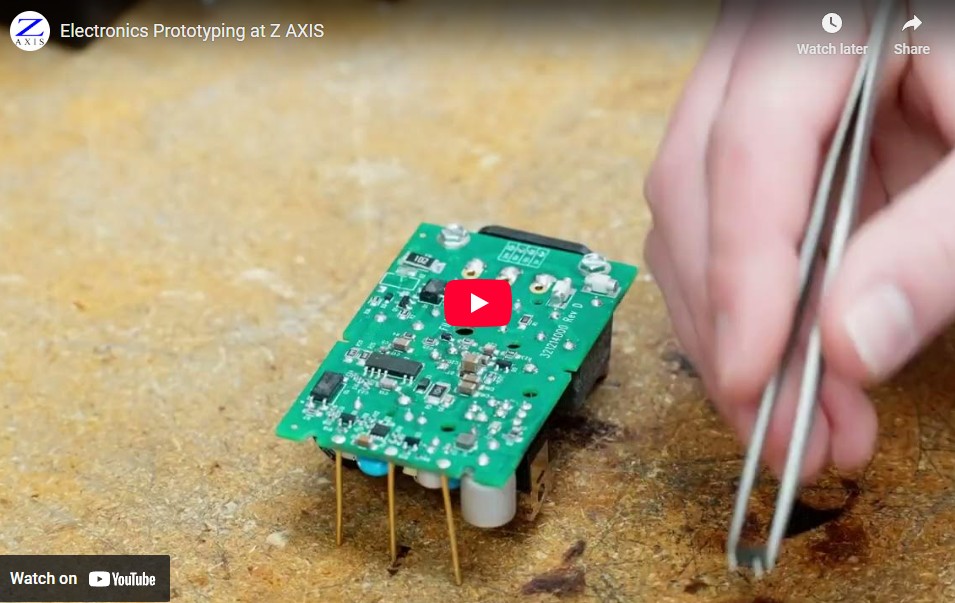

Laser Marking Promotes TraceabilityTraceability is important for quality control and supply chain transparency. If there’s a problem with a circuit board, electronics manufacturers need a way to find out what went wrong, including what automated optical inspection, or...

Laser Marking Promotes TraceabilityTraceability is important for quality control and supply chain transparency. If there’s a problem with a circuit board, electronics manufacturers need a way to find out what went wrong, including what automated optical inspection, or...